Face Frames

Whether you are trying to avoid a fast-approaching project deadline or simply looking to lessen the amount of work required in your shop or on-site, WalzCraft is happy to supply you with the Face Frames and fillers to complete your cabinetry project.

Our Face Frame (as known as Front Frame) products include Assembled and Ready To Assemble (RTA) Configurations, along with any S4S stock materials you may require to utilize as fillers, Countertop Moldings, Base & Casing Molding, or to assemble your custom Face Frame designs.

Give WalzCraft a try for your next cabinetry project and consider outsourcing your Face Frames in addition to other project components. Our Prefinished Face Frame products will be Stained & Sealed alongside your Cabinet Doors, Drawer Fronts, Moldings, and other components, and delivered to you conveniently in one shipment. Ready, set, install!

VIEW ALL

Product Education

Assembled Face Frames

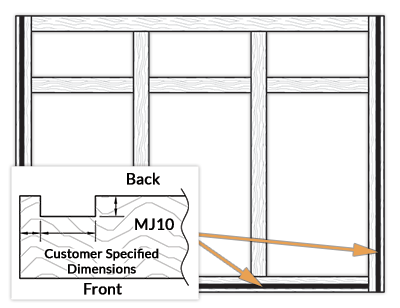

All of WalzCraft’s Face Frame products are completely made to order from the wood species and part sizes to the profiles and configurations. Assembled Face Frames are precision bored, with joints being glued and screwed together to ensure a stable product. Pocket screw joinery is WalzCraft’s preferred method and first choice for assembly unless otherwise specified. Biscuit joinery or Domino Tenon joinery may be used at all joints in lieu of Pocket Screws but must be specified when the order is placed. After assembly, Assembled Frames are sanded to a 220 grit and fladder sanded to a 180 grit.

*Please note that Assembled Face Frames will have a size tolerance of +/- 1mm on the overall sizes and +/- 1mm within each opening.

*Assembled Face Frames are only grain and color matched on the faces. All natural wood characteristics are acceptable on the inside edges. Standard Stile & Rail dimensions for Face Frames is 1 1/2″

Ready to Assemble (RTA) Frace Frames

Ready To Assemble (RTA) Face Frames are also bored and are alternatively shipped with screws specifically designed for use on the backside of Face Frames to conjoin the parts. WalzCraft labels each joint and also provides an assembly drawing for all RTA Face Frames. In some cases, RTA Face Frames may provide considerable savings in packaging and shipping costs in comparison to Assembled Face Frame products.

All Prefinished Face Frame products will be Stained & Sealed on two sides and all edges, then topcoated on the face and all edges.

Order Information

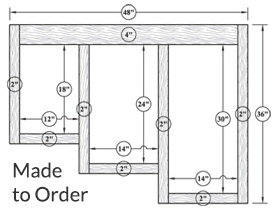

When ordering, it is very important to provide all of the dimensions for your Face Frame Configurations, including each part size, opening sizes, and overall width & height. Please provide WalzCraft with a completed Face Frame Order Form or your custom drawing, to clearly denote each dimension.

Dado and Rabbet Grooves are also available for all Face Frame products to simplify your cabinetry building and installation process. Simply specify the groove width and depth dimensions, as well as the placement from each Outside Edge of the Face Frame.

Prefit Cabinetry

For all of your Inset Cabinetry applications, WalzCraft is happy to offer both Assembled and Ready to Assemble (RTA) Face Frames where your Inset Doors and Drawer Fronts are precision sized to fit all Face Frame openings. It is recommended to provide clearly marked sizes for all Face Frame part sizes along with overall width and height dimensions in the form of a drawing. Please indicate which openings are to receive a prefit door or drawer front on your drawing.

WalzCraft welcomes orders in either millimeters or inches and asks that you note the gap desired between the Face Frame and your doors, the Face Frame and drawer fronts, and also between any two doors that will cover one opening.

Gap Options available in MM:

|

Gap Options available in Inches:

|

Our Face Frames are entirely built to your specifications, with each opening measured with calipers. Our skilled Craftsmen will subtract your specified gap from caliper dimensions and trim doors and drawer fronts to match the above sizes.

Outside Edge Options for Prefit Doors

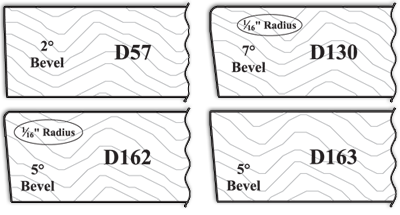

In a Prefit Cabinetry application, WalzCraft understands there is little room for sizing errors and offers four Outside Edge options that are designed to allow your prefit doors and drawer fronts adequate clearance from the Face Frame when opening and closing.

Recommended Outside Edges for Prefit Cabinet Doors and Drawer Fronts (Using an Outside Edge profile with a slight back bevel on Prefit Doors and Drawer Fronts will allow for adequate Face Frame clearance when opening.):

- D57 (Squared Edge with 2° Back Bevel)

- D130 (1/16″ Radiused/Broken Edge with 7° Back Bevel)

- D162 (1/16″ Radiused/Broken Edge with 5° Back Bevel)

- D163 (Squared Edge with 5° Back Bevel)

Please contact our Customer Support Team for more information about Precision Sized to Fit Doors and Drawer Fronts for Assembled or RTA Face Frames.

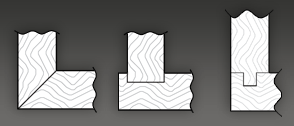

Beaded Face Frames

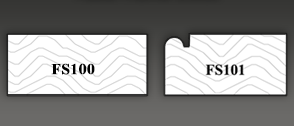

WalzCraft offers Integral Beaded Face Frames with Haunched Joints and Dado Grooves for Face Frame designs incorporating a beaded detail around each opening. This design style allows you to integrate our FS101 or FS103 bead detail onto your Face Frame without the need for an Applied Molding.

Integral Beaded Face Frames are constructed with Haunched Joints. When viewed from the front side of the Face Frame, a Haunched Joint results in a Mitered Joint at the beaded portion of the frame.

Ordering Guidelines

When ordering, please factor the size of the bead into your overall Face Frame dimensions. For applications that do not require a beaded look in every opening, WalzCraft does also offer a Beaded Applied Molding that can be substituted for the entire Face Frame.

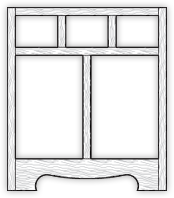

Standard Configurations

Base, Upper, and Tall

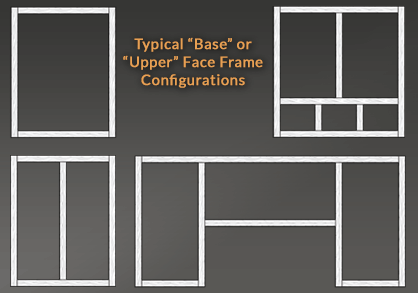

WalzCraft offers many typical Face Frame Configurations as a standard, with each arrangement having an assigned FF number. Configurations range from a single opening (FF100) to those with multiple openings arranged in various ways. Some Face Frame Configurations include openings for doors only, while others include openings for drawers or a mix of both.

When ordering, it is very important to provide all of the dimensions for your Face Frame Configurations, including each part size, opening sizes, and overall width & height. As a standard, Face Frame Part sizes are 1 1/2″ wide unless otherwise requested. All Assembled Face Frames will have a tolerance of +/- 1mm on the overall sizes and +/- 1mm within each opening.

Assembled Face Frames are only grain and color matched on the faces. All natural wood characteristics are acceptable on the inside edges. Face Frames are Stained & Sealed on two sides and all edges, and Top Coated on the face and all edges.

Please submit your Face Frame Configuration drawings to our Customer Support Team to obtain a price quote or request a custom configuration.

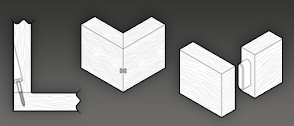

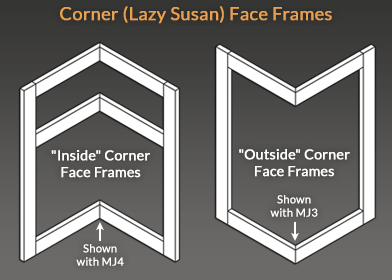

90° “Inside” & “Outside” Corner (Lazy Susan) Configuration

Transitional areas of cabinetry, such as corner cabinets (Lazy Susan applications), typically use 90° Inside and Outside Corner Face Frame Configurations. WalzCraft offers door only and door & drawer front face frame components for Inside and Outside Corner Configurations. Separate left (FF111 or FF113) and right (FF112 or FF114) Face Frames are required to complete a corner application. The rails utilize a standard butt joint where they meet at the inside corner unless otherwise specified.

Customers may specify one of WalzCraft’s optional Joint Assembly Methods. If you are ordering the left and right component with the optional 45° Inside (MJ4) or Outside (MJ3) corner miter joint, WalzCraft recommends using the Hoffman Dovetail Joining Method (JAM1) for assembly.

Inside & Outside Corner Face Frames are shipped partially assembled as left and right units, with the exception of Outside Corner Face Frames prefinished by WalzCraft with a SolidTone color. This frame style & finish combination is assembled first, then painted to help prevent any visible seams that may occur at the joints.

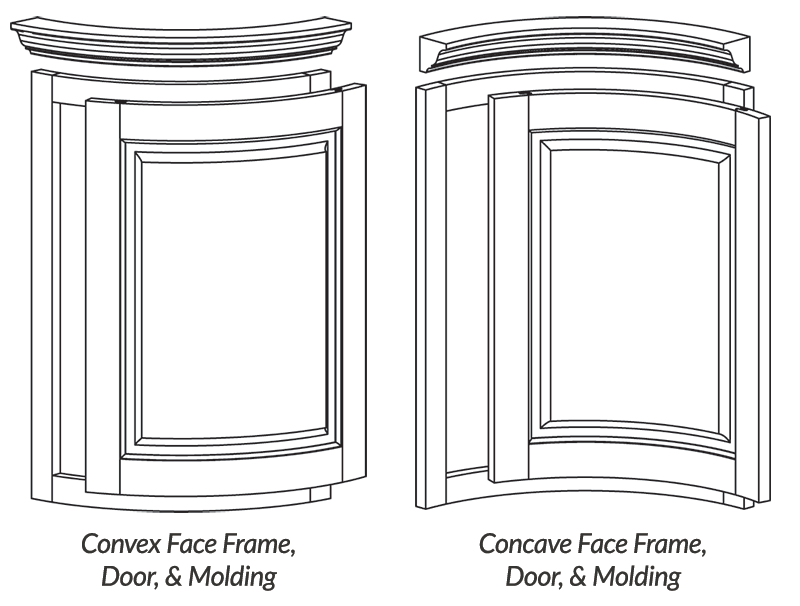

Convex & Concave Face Frames

WalzCraft offers Convex and Concave Curved Face Frame options for both overlay and prefit cabinet configurations. Pair with our Curved Doors, Drawer Boxes, and moldings to create unique kitchen islands, bathroom vanities, and custom furniture.

Construction

Curved Face Frames are available assembled in any of our Standard Radii Options and most of our Standard Face Frame Configurations. All face frame profile options (FS100-FS108) are available. WalzCraft does not offer Ready to Assemble (RTA) or individual face frame components due to the high risk of warping or twisting. Face frames constructed with a 24″ radius or greater use Pocket Screw Joinery. Face Frames built with a radius of less than 24″ use Domino Tenon Joinery where all the rails meet the stiles, and Pocket Screw Joinery on any center stiles.

To learn more about Radii Options & Ordering Instructions, visit our online catalog specifications for Curved Products.

Please contact our Customer Support Team to submit a quote request or to inquire about custom curved products.

Face Frame Options

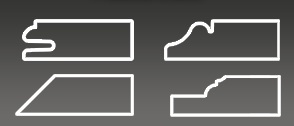

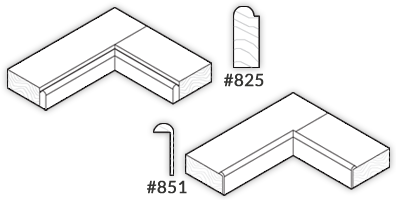

Beaded Applied Molding Options

As an additional feature for your Face Frame projects, WalzCraft offers Beaded Applied Molding Options.

Our Inset Beaded Applied Moldings are offered in various widths for both 3/4″ & 1″ thick Face Frames and sit flush with the face of the Stile & Rail parts.

Additional Beaded Moldings are also available for application to the Inside Edge of the Face Frame. The beaded portion of the molding overlaps the face of the Stile & Rail parts and provides a raised beaded look on the Face Frame.

Please order your Face Frames with the bead factored into the overall width dimensions of your Face Frame parts.

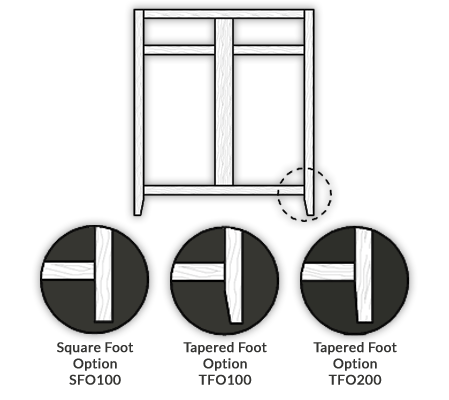

Square & Tapered Foot Options

To give your Face Frame Configuration a bit of a furniture feel, WalzCraft offers Square & Tapered Foot Options.

When ordering please specify:

- Foot Pattern: SFO100, TFO100 or TFO200

- Length of the Foot (3 1/2″ or 4″ are typical)

- Taper Start Point (from bottom of the Face Frame) for TFO100 & TFO200 Only

- Taper Width (remaining flat dimension will vary with stile width) for TFO100 & TFO200 Only

When applying a Foot to a Face Frame, please order the Face Frame at the height including the Foot Length.

Toe Kick Valances

Toe Kick Valances are a popular way to dress up any Base Cabinet Face Frame Configuration. They are available in one-piece solid wood or MDF, and in various styles to compliment many of WalzCraft’s door styles.

Toe Kick Valances are a popular way to dress up any Base Cabinet Face Frame Configuration. They are available in one-piece solid wood or MDF, and in various styles to compliment many of WalzCraft’s door styles.

Cabinet Feet

To create a polished look for your cabinetry design, WalzCraft offers Cabinet Feet components in various styles, shapes, and sizes. Cabinet Feet are a great way to add a furniture look to cabinetry that appeals to any decor style.

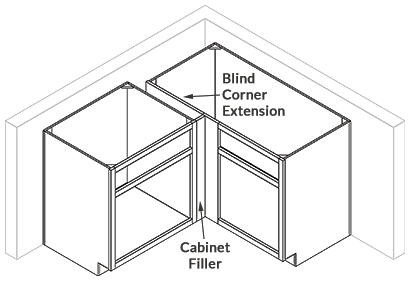

Cabinet Fillers and Blind Corner Extensions

Save time by ordering Cabinet Fillers and Blind Corner Extensions with your next Face Frame Order.