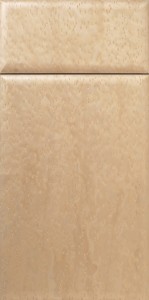

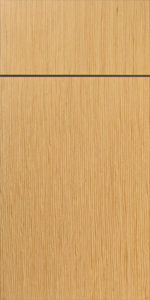

Architectural Grade / Reconstituted Veneer Cabinet Doors

Architectural Grade / Reconstituted / Composite Veneer is an environmentally friendly alternative to other rare and exotic wood species veneers more commonly recognized in the woodworking industry. Reconstituted Architectural Grade Veneer is a man-made wood product created from renewable wood sources and therefore offers exceptional grain and color consistency desired in most Contemporary Cabinet Doors.

Often times, Reconstituted Veneer Doors & Drawer Fronts are found in Contemporary designs where the entire wall and cabinets require a continuous grain match. This veneer is considered suitable for a natural/clear coat (no stain applied) finish and other light stain colors.

WalzCraft offers Reconstituted Architectural Grade Veneers on slab style doors (Style 60) and drawer fronts (Style 60*) made up of an MDF core with Reconstituted Veneer applied to the face and back sides of the door/drawer front. These products are available in sizes up to 48” in width and 96” in height, as well as various thickness options.

If consistency in grain or color is important for individual doors and/or drawer fronts that will be installed directly above or below one another, we highly recommend utilizing WalzCraft’s Continuous Grain Option. With this option, you can have up to 120″ of grain through your doors and/or drawer fronts.

When ordering you will need to provide your choice of Edgeband Treatment and have the option to customize the Edgeband Application Sequence and Edgeband Grain Direction if you so choose.

Product Education

Definition

Architectural Grade / Reconstituted / Composite Veneer is a wood veneer produced using a fast-growing tropical wood species, often times Obeche & Poplar. The veneers are dyed and laid up to ‟mimic” the look of a particular wood species. Veneer Sheets are made by laminating a block of veneer leaves together. The block is then sliced so that the edges of the laminated leaves become the “grain” of the composite veneer.

This veneer is relatively free from defects and has outstanding color and grain consistency from sheet to sheet.

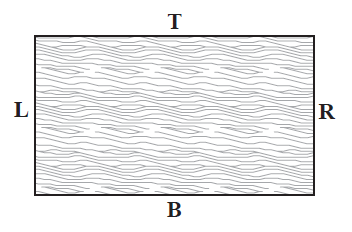

Edgeband Application Sequence

WalzCraft’s standard edgeband application sequence is to apply the edges in the following order: Top, Bottom, Left, Right. Our standard sequence means that the butt joint of the edgeband will be visible on the top and bottom of the door or drawer front. For an additional charge, you have the option to determine the order in which the edgebanding material.

Unless otherwise specified, WalzCraft’s standard sequence will be used.

Edgeband Grain Direction

WalzCraft’s standard edgeband grain direction is to apply the High Pressure Laminate edgebanding in a Lineal direction. However, when using HPL-4 (Laminate Edgeband), you have the option to choose Front to Back grain direction for each edge for an additional charge. Applying the edgeband in a front to back direction on either the top & bottom or left & right sides the look of a solid wood door or drawer front.

Unless otherwise specified, WalzCraft’s standard will be to apply the HPL edgebanding in a Lineal direction. Please add charge per square foot if deviating from WalzCraft’s standard. Front to Back grain direction is limited to a maximum length of 48″.