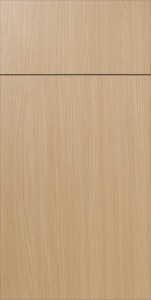

Melamine & High Pressure Laminate (HPL) Doors

Melamine & High Pressure Laminate (HPL) Doors & Drawer Fronts are available in a slab style that offers a sleek and stylish look free from embellishments. Due to the durability and functionality of Melamine and HPL, these products are suitable for both residential and commercial applications and are commonly incorporated into contemporary kitchens, bathrooms, closets, furniture, and more.

These doors and drawer fronts are clean and minimalist in their form, but with WalzCraft’s custom design options customers have the opportunity to create a truly custom look. Options include face, back, and edgeband material selections in a broad range of colors, sheen choices, textures, and designs including solids, geometric patterns, and wood grain. Add hinge boring, wood finger pulls, or our Continuous Grain Option to further customize your design.

Start your custom design today by exploring WalzCraft’s Melamine & HPL Door & Drawer Front Options below.

VIEW ALL

Product Education

Ordering Options & Specifications:

- Order Style 2223 Doors & Style 2223* Drawer Fronts

- Available in 5/8″ or 3/4″ thicknesses

- Options: White, Almond & Maple Melamine (other Melamine colors available upon request)

Manufacturing Option

Ordering Options & Specifications:

- Order Style 2224 Doors & Style 2224* Drawer Fronts

- Available in 5/8″ or 3/4″ thicknesses

- To place a quote or order, please provide the following manufacturing options:

- Core Material: MDF.

- Edgeband Material: PVC or Laminate Edgebanding and the Edgeband Color.

- Choose one of our HPL Stock Colors/Finishes or specify an HPL Manufacturer: Formica, Wilsonart, Nevamar, or another Manufacturer of your choice and the color.

Manufacturing Option

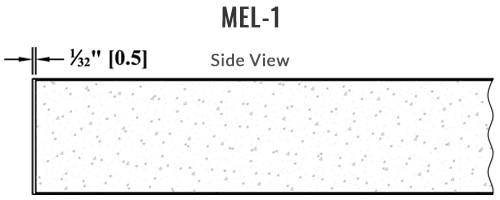

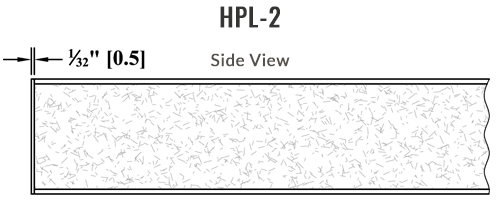

HPL-2

- HPL is applied to the face and back of the door, then a 1/32″ PVC Edgeband is machine applied.

- Edgeband glue line is left exposed.

- Only available with D7 OSE.

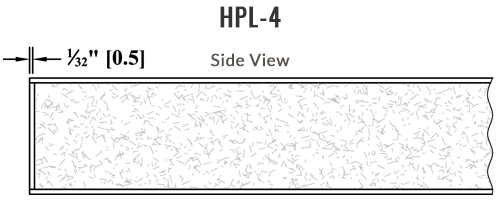

HPL-4

- A 1/32″ HPL Edgeband is machine applied, then a HPL is applied to the face and back of the door hiding any exposed edgeband glue lines from the face or back.

- With HPL-4, you have the option to specify the Edgeband Grain Direction.

- Only available with D7 OSE.

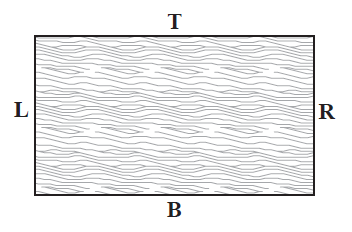

Edgeband Application Sequence

WalzCraft’s standard edgeband application sequence is to apply the edges in the following order: Top, Bottom, Left, Right. Our standard sequence means that the butt joint of the edgeband will be visible on the top and bottom of the door or drawer front. For an additional charge, you have the option to determine the order in which the edgebanding material.

Unless otherwise specified, WalzCraft’s standard sequence will be used.

Edgeband Grain Direction

WalzCraft’s standard edgeband grain direction is to apply the High Pressure Laminate edgebanding in a Lineal direction. However, when using HPL-4 (Laminate Edgeband), you have the option to choose Front to Back grain direction for each edge for an additional charge. Applying the edgeband in a front to back direction on either the top & bottom or left & right sides the look of a solid wood door or drawer front.

Unless otherwise specified, WalzCraft’s standard will be to apply the HPL edgebanding in a Lineal direction. Please add charge per square foot if deviating from WalzCraft’s standard. Front to Back grain direction is limited to a maximum length of 48″.