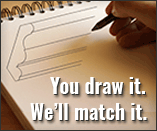

Dark Brown - Dry Wipe - Light.jpg)

Glaze Color: Brown

Glaze Method: DWFP

- Stain: Honey (Wiping Stain)

- Wood: Alder

- Glaze Color: Brown

- Glaze Method: Dry Wiped – With Flow Pen Method (DWFP)

- Glaze Intensity: Light (LG)

Dry Wiped With Flow Pen Glaze

This method utilizes a brush, rag, or spray gun to apply glaze to the entire face and profiled areas of the product. The glaze is then wiped away with a clean, dry cloth, leaving the glaze build up at the desired level of intensity. Using a flow pen, the glaze is then applied to the crevices, corners, and profiled areas.

This method will alter the appearance of the original color and wood species combination and causes the color to vary between the front and back side of the product. Due to the glazing effect, it also becomes necessary to apply glaze to all sheet stock, moldings, and accent components.

*You must select either “Light” or “Heavy” intensity. The difference is the amount of glaze build-up left in the corners on the center panel.

Wiping Stains

Wiping stains are applied by spraying the stain onto the product and immediately wiping off the excess material with a rag. This process is by far the most common finishing method in the wood industry.

Common Wood Species and Grade combinations when using this stain color:

- Alder – (Select/Premium Grade)

- Alder – (Natural/Standard Grade)

- Alder – (Rustic Grade)

Color Samples

This is an In-Stock Color Block and is available for purchase as an Individual Color Block or as part of a Color Block Set.

Disclaimer for Color

Actual product color and detail may vary due to individual computer preferences and monitor settings. We highly recommend ordering an actual product sample of the species and stain color to eliminate any confusion.

Please contact our Customer Support Team to place your order.

- Black - Flow Pen - Light.jpg)

- Black Glaze - Solvent Wiped - Light.jpg)

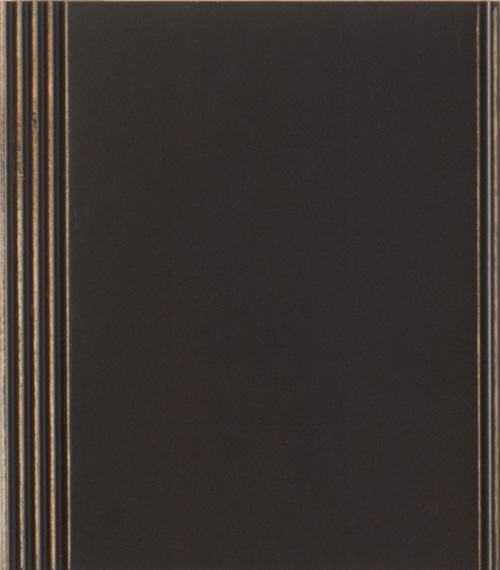

- Dark Brown - Dry Wiped Light.jpg)

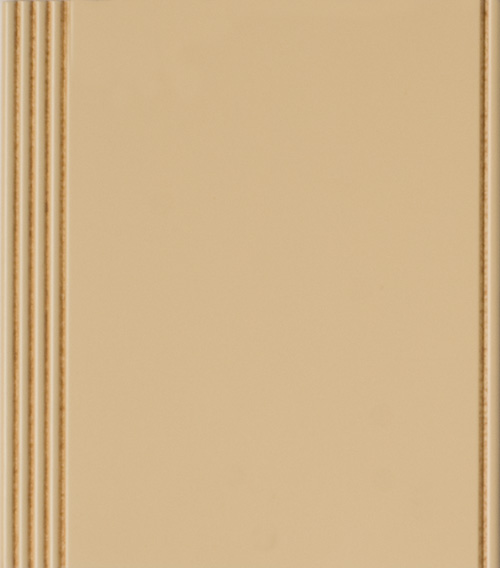

Dark Brown - Solvent Wiped - Light.jpg)

- Dark Brown - Dry Wiped - Light.jpg)

- Dark Brown - Dry Wiped - Light.jpg)

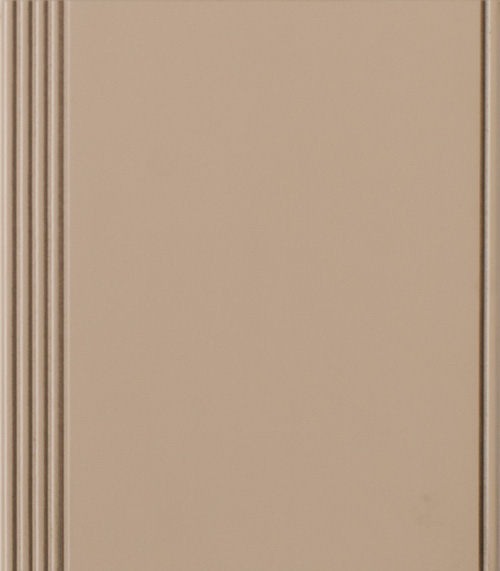

- Cream - Dry Wipe - Light.jpg)

- Dark Brown - Dry Wiped - Light.jpg)